Roofing

Roof Edges in High-Wind Zones

In high-wind zones it is recommended – as a minimum requirement - that a fully adhered roof membrane underlayment be installed at roof eaves and roof rakes. This is a minimum requirement. The fully adhered underlayment can help roof edges resist high wind pressures.

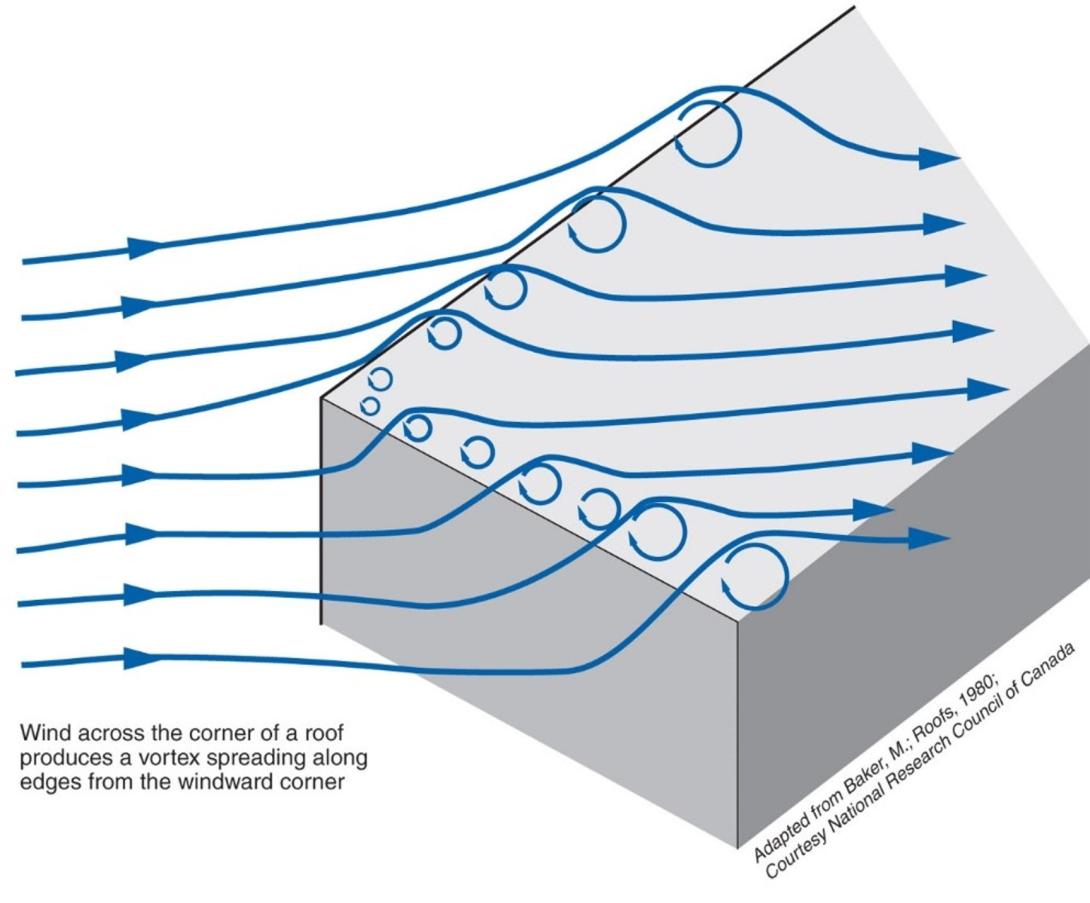

In high wind zones, the greatest point of stress in roof assemblies is at roof edges. Here, roofs experience the highest positive and negative air pressures. In addition, roof edges can also experience the greatest rainwater loads. Roof assemblies need to be able to resist the wind pressures that can act on them during high wind events such as hurricanes.

A fully adhered roof membrane underlayment should be installed at roof eaves and roof rakes. For improved performance and reduced risk, install the membrane underlayment over the entire surface area of the roof deck. The membrane can be a single-ply membrane such as TPO, EPDM, or PVC, a built-up modified bitumen, or fluid-applied membrane. If a mechanically fastened underlayment is installed instead, you must take additional air sealing and water control measures at the roof deck to ensure acceptable performance in high wind zones.